When you decide to remodel, kitchens are almost always the best investment in your home. Spending big bucks in the central terminal of your home makes sense, because that is where you spend almost all of your time. And if your kitchen isn’t the central terminal because an ancient architect had no idea that we want openness, then it is time to knock down a few walls {we love knocking down walls} tweet this

I’ve remodeled several kitchens this year and the one area to take the biggest chunk out of your moola is the cabinets. This put me on a quest for the best source for cabinets . Before I tell you why I became a cabinet dealer, let’s do a little kitchen cabinet primer. A little hornbook, if you will, to tuck into your back pocket (next to the wallet) to help you talk the talk.

The construction of kitchen cabinets isn’t something a person really pays attention to. I know I didn’t back in the day when I was an accountant. Of course, when you want to rip out your old smelly, fugly cabinets, you of course begin to wonder. I of course, had several courses {insert singing – “a horse, is a horse, of course, of course……………”} in college about residential kitchens and this last October I attended a three day “cabinetry” training class.

Here is the down and dirty of kitchen cabinets:

Things to Know About Kitchen Storage

Cabinets are after all, well, just storage and getting the best possible storage can make your life a whole heck of a lot easier.

Production Methods:

There are three general production methods (always three, right?)

- Stock cabinets are mass produced, preassembled, awaiting quick shipment, generally to a big box store and come in “stock” sizes starting at 9” and increasing by 3” increments (9”, 12”, 18” etc.). The materials, finishes, and door styles are limited. $

- Semi-custom cabinets are constructed when ordered, generally in stock sizes, but custom modifications can be made. There is greater flexibility in terms of size, materials, finishes, and options. $$

- Custom cabinets are made to order by a local artisans or craftsmen with few limitations on size, design, arrangement, materials, wood species or options. $$$$$

The production technique does not necessarily have a mutual relationship to the cabinet quality. This is determined by the material chosen as well as the joinery and bracing used in the actual construction. I guess what I am trying to say here, is that you could get custom cabinets that are crappy based on poor construction or high quality stock cabinets that have superior construction. As I found out, it all depends.

Sizes:

- Standard widths start at 9” and increase at 3” increments.

- Standard depth is 12” for wall cabinets and 24” for base cabinets.

- Standard heights are 34 ½” for base cabinets. Wall cabinets generally start at 12” and go to 42.”

- Tall cabinets are 84”, 90” or 96” (depending on the height of your ceiling – and always, always have your cabinets go to the ceiling, please………….)

This is important to know, because if you look close at your cabinets you can see where they are joined. Low and behold, if you measure them you will see this size pattern {it is really just blocks put together)

Frames:

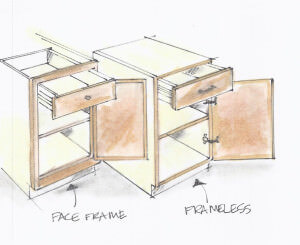

- Framed cabinets are the most common style in North American and consist of a frame (sometimes called a face-frame) that is attached to the front of the cabinet with doors attached to the frame.

- Frameless cabinets (also called Euro-style) have no face frame on the front of the cabinet box and the doors are attached to the inside of the box. Frameless cabinets give more access to the interior contents and the hinges don’t show.

Hardware:

Cabinet hardware consists of hinges, latches, pulls, and knobs. The selection of hardware can greatly impact the visual quality of cabinetry, so carefully consider size, shape, and finish.

Door and Drawer Styles:

- Doors and drawer fronts can be inset within the frame or overlaid on framed cabinets.

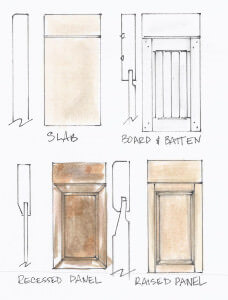

- Panels are generally referred to as slab, board and batten, recessed panel, or raised panel.

- There is a variety of styles for each panel depending on the manufacturer.

There you have it, the low-down on cabinetry.

How I became a Cabinet Dealer

I always had custom cabinets fabricated for my designs, but this year, I decided I needed more control and streamline approach to designing cabinets. I interviewed many manufacturers and craftsmen and found a manufacturer that I felt represented a style and philosophy that was similar to mine. In other words – a cabinet line with enough options, good quality construction, envrionmenatlly friendly and at a price point that made sense. My decision was to become a Canyon Creek dealer. This is good for you, because I have done all the work and research for you. All you have to do is the fun stuff – like pick one of the three options I will present to you when I design your kitchen.

- The plant is on the West Coast. This saves on freight (and is good for the environment)

- There is two levels of construction – an economy line (that is beautiful) and a premier line (even more gorgeous) that has loads of flexibility (pretty much custom)

- The cabinets are frameless – THIS IS SO IMPORTANT! Folks – frameless cabinets just look and function better – that is all there is to it (in my opinion anyway)

- And the best part – they are eco-friendly! Enviro-friendly manufacturing and environmentally preferred construction and materials. Good stuff, man!!!

Hey, you are in like Flynn and can talk the talk when it comes to kitchen cabinets.

Are you considering remodeling your kitchen? Check out our exclusive ReFAB Clinic package and have a successful remodel

Make sure you sign up and download my eBook, Your Room In The Nude. It is full of decorating tips you’ll want to have in your back pocket.

Dream, Scheme, and Sketch to Design Clarity

Robert Jennison

| 5 December 2013That’s the best explanation of cabinets I have seen ever. great JOB.

Six Expert Kitchen Cabinet Ideas That Will Impress Your Chef - Kathleen Jennison

| 7 September 2015[…] Kitchen cabinets are a big deal. It defines your kitchens style and whatever you select is gonna cost ya, so you better like it. When you need kitchen cabinet ideas, you should start with understanding the basics and get those down pat. If you want more detail, check out this blog post. […]

How Much Will a New Kitchen Cost? – Part II | KTJ Design Co

| 18 December 2016[…] can read this blog to learn all about […]

Kevin Nathan

| 20 June 2017Here is great information about kitchen cabinet construction. Remodeling a bathroom comes right behind a kitchen with home projects that pay off. Thanks for this great blog.